Samara National Research University and JSC “Power Machines” have established a joint design bureau (DB) Vodorod SM to conduct development of technology for the first Russian gas turbine plant using methane and hydrogen fuel. The DB has been established on the basis of the University’s Research and Education Centre for Gas-Dynamic Studies (REC GDS). The DB’s team will consist of 15 specialists. The DB’s Scientific and Technical Council works under the leadership of Alexander Ivanovsky, the General Designer of JSC "Power Machines". While the DB itself is headed by Sergey Matveev, REC GDS senior researcher, PhD in Technical Engineering .

“Our design bureau will be focused on development of combustion chambers for energy gas turbine plants operating on alternative fuels with high hydrogen content. This is a new area in the Russian energetics; no native analogues exist so far. Our first project will be to develop a combustion chamber for a promising 65 MW GTE-65.В gas turbine unit. The unit will be fueled by methane-hydrogen mix, which will help increase the turbine’s power and reduce the quantity of harmful atmospheric emissions,” says DB’s head Sergey Matveev.

According to the preliminary research, use of methane and hydrogen mix with 40-50% hydrogen fraction will improve the gas turbine plant’s power by approximately 10%. Such energy units can be used in large industrial enterprises, or for supply of heat and electricity to small towns or metropolitan districts.

Addition of hydrogen will ensure more thorough combustion of fuel, thereby reducing emission of carbon monoxide and unburnt carbon; besides, it will bring down total СО2 emissions and fuel consumption. During design and development of the combustion chamber, Samara scientists will have to optimize the combustion chamber’s design, determine the most effective fuel mix, solve the problem of acoustic pulses occurring during combustion of methane and hydrogen fuel, and work out how to minimize NOx emissions.

Modeling of combustion processes in the course of the research and development work will engage the high-performance computing cluster of Samara University. The experimental combustion chamber model will be manufactured on a 3D printer in the university’s additive technology lab. The methane-hydrogen mix combustion experiments are scheduled for February 2021. Overall, the works for development of the innovative combustion chamber will take several years. Development of the technical design of the gas turbine plant combustion chamber is scheduled for completion in 2023; afterwards, the development prototype will be manufactured in a factory.

Rector of Samara University Vladimir Bogatyrev:

Exploring new forms of cooperation with traditional partners focused on creation of advanced hi-tech products is one of the priorities of Samara University development strategy.

This year, two design bureaus have been opened on the basis of our university in partnership with the leading Russian technology companies - Power Machines and UEC. In our partnership with Power Machines, we contribute our unique experimental base and experience of fundamental research and applied developments in creating effective fuel mixes and innovative combustion chambers for gas-turbine engines.

Such cooperation is an effective tool for ensuring technological leadership of the country and provides for successful cooperation between the leading research centers and real economy sector, increasing the scope of research in flagship knowledge-intensive fields.

For reference:

Power Machines — global power engineering company, one of the five world industry leaders in terms of installed-equipment volume. The company has developed a wealth of experience and expertise in the engineering-design, manufacturing and supply of equipment sets for thermal, nuclear and hydro power plants. The company’s core competency and competitive advantage extends to implementing integrated turn-key projects in the electrical power field. Power Machines are part of Severgroup LLC.

In 2018, Power Machines have started development of the indigenous line of energy gas turbines of two standard sizes – GTE-65 and GTE-170. The first GTE-170 turbine has been launched into production; GTE-65 revision has been completed for the turbine which was previously manufactured but not completely tested. GTE-65 and GTE-170 are being manufactured by LMZ (Leningrad Metal Plant). The research and development plan is implemented with participation of the leading Russian R&D companies; the manufacturing facilities are being updated. In 2019, Power Machines have won a contest organized by the Russian Ministry of Industry and Trade for subsidizing research and development works in this project.

***

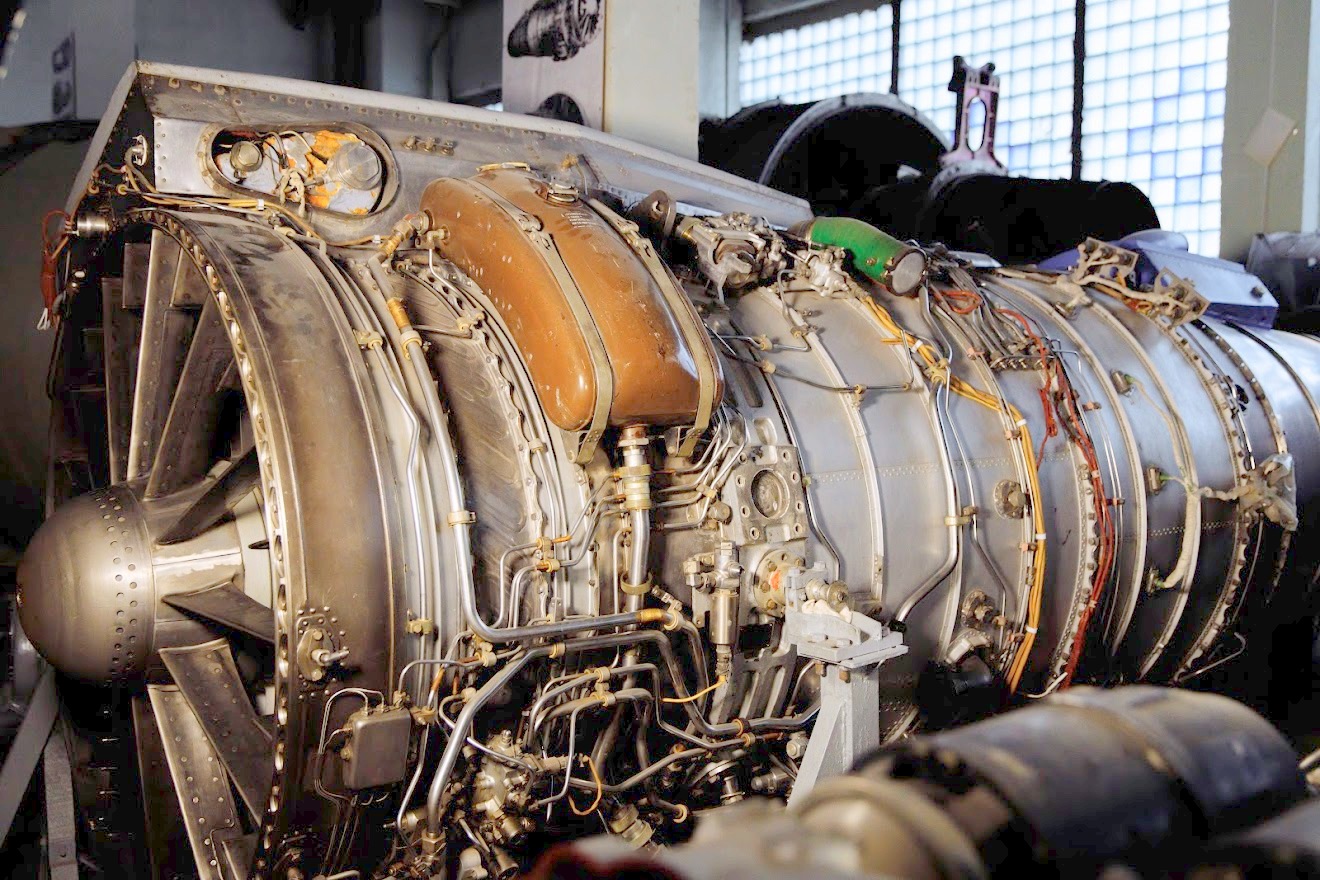

Research of hydrogen fuel applications has been conducted in Samara (Kuibyshev) since 1960s. A unique NK-88 engine running on liquid hydrogen was created in the engine-building design bureau under the leadership of Academician Nikolai Dmitrievich Kuznetsov.

In its calorific value hydrogen significantly surpasses aviation kerosene, while being absolutely friendly to the environment. The core team of the engineers who worked on that engine included graduates of the Kuibyshev Aviation Institute (now the Samara National Research University).

The NK-88 engine was installed on an experimental Tu-155 aircraft that first took off on April 15, 1988. The world's first aircraft to use hydrogen fuel had passed a series of tests successfully, having made several international flights in Europe, including one to Hanover, Germany, to a conference on the use of cryogenic fuel in aviation.

Later, a project of Tu-156 aircraft was developed to fly running NK-89 engines fueled by liquefied natural gas, but the program for aviation cryogenic fuel was terminated due to financing shortage. Currently, the NK-88 engine is an exhibit at the Center for the History of Aircraft Engines at Samara University.

In the early 2000s, employees of the Department of Thermal Engineering and Thermal Engines and Research and Education Centre for Gas-Dynamic Studies (REC GDS) ofSamara University have launched new studies to improve the energy efficiency of cryogenic systems and plants via low-potential energy of cryoproducts. Since 2020, a cryogenic equipment laboratory has been actively developing on the basis of S&E GDRC. The main thrust of the laboratory is to compute, design and create highly efficient power plants and engines operating on cryogenic fuels, including LNG. Scientific and applied studies by the laboratory are carried out with financial support of the Ministry of Education and Science of Russia (project No. FSSS-2020-0019), planned for 4 years.