Samara National Research University scientists together with their colleagues from Samara State Medical University are developing a unit for medical institutions that will significantly reduce the cost of cranioplasty – plastic surgeries to correct skull defects resulting from craniocerebral injuries or after neurosurgical interventions. The unit will enable rapid and less expensive manufacture of personalized (patient-specific) titanium implants right in the medical institution using the method of incremental sheet forming from sheet titanium blanks. The project has won the competition under the UMNIK (“wiseacre”) program and received financial support from the Innovation Promotion Foundation.

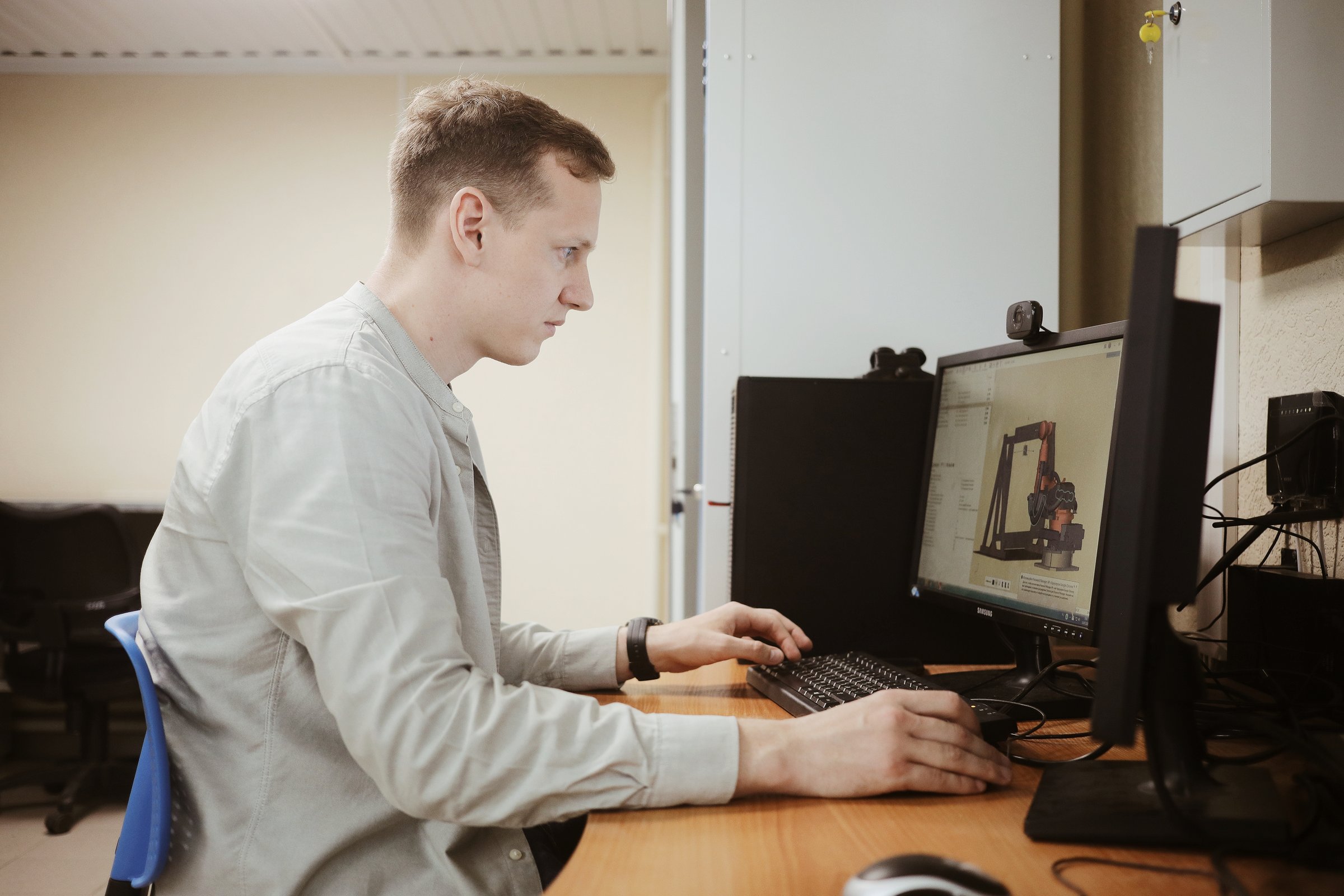

“Today personalized titanium implants to replace missing parts of bone tissue are usually manufactured using additive technology – on expensive 3D printers and from high-value titanium powder which costs about 7-8 times more than a same-weight piece of titanium sheet. Moreover, 3D printing equipment requires maintenance by highly-qualified specialists which makes it unprofitable for a medical institution to purchase, maintain and use it; therefore, doctors have to order implants from a specialized company. The cheaper and easier-to-manage machine we are developing will use incremental sheet forming technology and sheet titanium to produce lower-cost personalized implants right in the hospital, thus making them more affordable for patients. Even employees of the medical institutions will be able to operate the software of this machine after appropriate training,” said project manager Ilya Petrov, an engineer at the Department of Metal Forming of the Institute of Aviation and Space-Rocket Engineering at Samara University.

The input material will be sheets of domestic BT6 grade titanium alloy widely used in the Russian aerospace industry. The incremental sheet forming technology consists of gradual local deformation of individual parts of a sheet blank according to the program settings. The part is manufactured by moving the tool along the pre-programmed contour, as if a team of miniature robotic smiths moved along the workpiece, deforming it step by step with absolute precision. The Samara scientists propose that the part processing is performed synchronously on both sides, by two “robotic teams” simultaneously. Determining the right processing algorithm is essential.

“The innovative feature of our system is that both deforming tools, main and auxiliary, will be made in the form of miniature three-axis manipulators using the same control principle as modern 3D printers. The auxiliary tool will provide deformation on the reverse side of the workpiece so that the accuracy of the product manufacture will be comparable to the accuracy of modern 3D printers. This design philosophy will help create a compact device that can be installed on a regular writing desk," said Ilya Petrov.

According to him, there are no such medical tools either in Russia or in the world thus far, and in the future, scientists plan to patent their development. The estimated cost of the unit is about 3 million rubles. The cheapest 3D printer that can manufacture titanium personalized implants currently costs about 7.5 million rubles. The experimental model is due by the end of 2022.

For reference

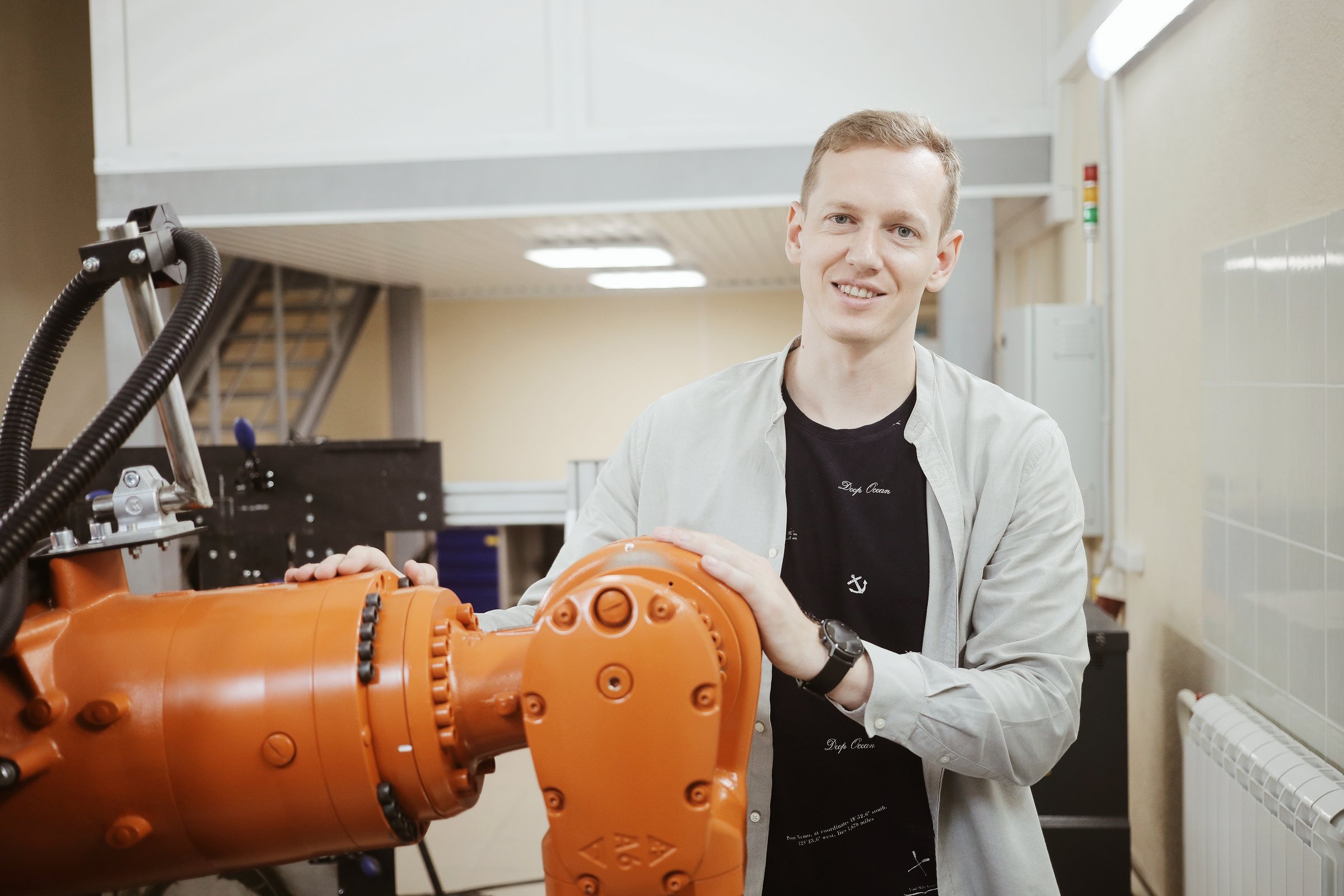

* Samara University is a federally recognized center of excellence for incremental stamping. In 2020, the university created an incremental stamping robotic system that is unique in Russia and works to simultaneously solve scientific, educational and pilot production tasks. The equipment can use blank sheets to produce a wide range of non-serial products, from knight armor and vintage car parts to structural elements for spacecraft and launch vehicles under development.

** “UMNIK” (“wiseacre”) (Participant of the Youth Scientific and Innovative Competition) is a program intended to identify and support young scientists striving for self-realization by means of innovative activities. UMNIK has been implemented since 2007. During this time, the program had more than 70 thousand participants including over 12 thousand winners. The program is carried out in five areas. The program winners receive funding in the amount of 500 thousand rubles for a period of two years to develop a scientific and innovative project.

*** According to open sources, over 43,000 people hospitalized with craniocerebral injuries undergo surgery in Russia annually. A decompressive craniotomy is performed in about 80% of cases. After surgery and treatment, most patients require implants to replace removed portions of the skull bones.