The project of scientists from the Engineering Centre of Samara University will allow the making multipurpose and environmentally friendly gas-turbine power plants operating on various fuels, including methane-hydrogen blends and hydrogen. These plants can be used as autonomous sources of electrical energy for large settlements or small enterprises, e.g. in remote areas of the Arctic or Siberia where there are no centralized electrical grids. The project implemented in the interests of ODK-Kuznetsov PJSC won in the contest of the Innovation Fund of the Samara Region and was granted financial support of 12 million rubles.

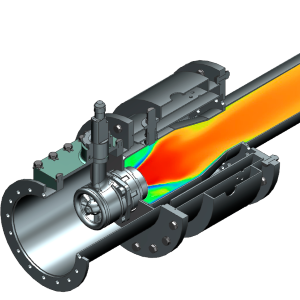

“In the framework of the project we work out structural solutions to create an environmentally friendly low-emission combustion chamber and a multipurpose burner device that makes it possible to use various kinds of fuel in gas-turbine engines — the use of kerosene, diesel fuel, hydrogen, and methane-hydrogen blends is considered along with use of common methane. We need to achieve the maximum unification of the burning device so that it would be suitable for gas-turbine engines of various capacities without requiring any changes in their structure or providing for insignificant changes only. It will allow modifying the lines of gas-turbine engines powered by natural gas used in power plants and at gas transmission stations on a massive scale with minimal expenditures. Due to a new combustion chamber and a unified burner, the modified engines will be much more versatile in terms of the use of various fuels, as well as more environmentally friendly — due to significant reduction of hazardous substances and possible use of hydrogen or methane-hydrogen blends as a fuel,” Ivan Zubrilin, Director of the Engineering Centre of Samara University, said.

According to him, participants of the project implementation of which involves employees of various scientific centres and laboratories of the University already have a few options for structural solutions, and these options will be analyzed using the multicriteria optimization methods. Digital models of the combustion chamber will be designed and experimental researches will be conducted — both in the laboratories of the University and using ODK-Kuznetsov manufacturing capacities. Based on the results of the project an experimental prototype of a burning device is planned to be made. NK-14ST was chosen as a basic engine for the primary modification. This engine series-produced in Samara since 1995 and mostly used as a part of gas-compressor units is notable for high resilience, simple maintenance, and high efficiency. Besides, the engine can work under any climate conditions.

“Power plants based on such an engine with a capacity of 8–10 MW can provide about a thousand households with electric energy, i.e. a settlement or a small enterprise in a remote area. Furthermore, we plan to conduct experiments with NK-36ST; it’s another engine with a capacity of 26 MW. In the course of our researches we face the task to demonstrate that the solution we develop can be used in the engines of various power categories,” Ivan Zubrilin noted.

According to him, to manufacture a low-emission combustion chamber and a multipurpose burner additive technologies are expected to be used, i.e. heat-resistant structures for the engine will be made using a 3D printer. The scientists assume, in the course of work they will also have to modify a few national engineering analysis programs for their purposes — they will be made more suitable for this project by changing the program code — a respective agreement has been reached with software developers. The project is planned to be completed by June 2023.

Alexander Ulitichev, Chief Structural Engineer for NK-12ST, NK-14ST, and NK-14ST-10 Engines of ODK-Kuznetsov PJSC:

— This project has great significance for ODK-Kuznetsov PJSC. Firstly, it can help to strengthen the attractiveness of NK-14ST gas-turbine plants and those of other series due to the reduction of hazardous emissions. Secondly, the project will allow expanding the validation basis for burning models which eventually will allow reducing the cost and the development cycle of a low-emission combustion chamber. Thirdly, the project will create a large premise for works with hydrogen fuel. And, of course, the joint project of two engineering teams — one from ODK-Kuznetsov PJSC and another from Samara University — will promote the development of the Advanced Engineering Airspace School (AEAS) “Integrated Technologies in Manufacturing of Aviation and Space Machinery” established within the University this year and development of a digital twin laboratory. ODK-Kuznetsov PJSC is one of the industrial partners of the University in the AEAS project.

For reference

* The objective regarding hydrogen energetics development is outlined in the key sectoral strategic planning document — the updated Energy Strategy of the Russian Federation for the Period Until 2035. Upon the Executive Order of the Government of the Russian Federation No.2634-r dated October 12, 2020, the action plan (‘Roadmap’) was established to develop hydrogen energetics in Russia until 2024, the one aimed at production scale-up and expansion of the hydrogen application scope as an environmentally friendly energy source.

The relevant objectives are the improvement of sustainability of the existing gas-turbine plants powered by methane and the examination of the opportunities for the replacement of methane with hydrogen or methane-hydrogen blends. The addition of hydrogen ensures a more thorough combustion of fuel, thereby increasing the plant’s capacities and reducing the emission of carbon monoxide and unburnt carbon; besides, it reduces total СО2 emissions and fuel consumption. Thus, the use of a methane-hydrogen blends with 40–50 % hydrogen volume fraction can increase the capacities of the gas-turbine plant by about 3–5 % and reduce the fuel consumption three- or four-fold.

** The Engineering Centre of Samara University was established in 2021 based on the results of the open competition for grants in the form of subsidies from the federal funds for the establishment and development of engineering centres in Russia arranged by the Ministry of Science and Higher Education of the Russian Federation. Samara University made it to the list of 11 first-priority winners of the competition. The victory had become possible due to well-coordinated work with participants of the global scale REC consortium “Engineering of the Future” and the support provided to the Engineering Centre personally by Dmitry Igorevich Azarov, the Governor of the Samara Region.

The Engineering Centre’s priority areas of work include the development of digital intelligent technologies for mechanical engineering and digital twins, promising gas-turbine engines and plants, as well as the development of additive technologies and industrial robotics, training and re-training of high-grade specialists for engine construction enterprises of Russia.

The Engineering Centre is developing in close cooperation with its strategic partner — ODK-Kuznetsov PJSC. The projects implemented here will be key elements of the research program for the development of REC “Engineering of the Future” in terms of technological and educational initiatives of the Engine Construction platform.

*** ODK-Kuznetsov PJSC is a part of the United Engine Corporation. It is Russia’s leading enterprise in the development, manufacturing, technical support and maintenance and repair of gas-turbine aviation engines, liquid rocket engines, gas-turbine plants for ground use in the gas industry, energetics. The gas-turbine engines manufactured at the enterprise (e.g. NK-12ST, NK-14ST, and NK-36ST) are incorporated into gas-compressor units of Gazprom PJSC; they are used in the oil and gas industry of Russia, gas companies of the Republics of Turkmenistan, Uzbekistan, and Kazakhstan.