In total, in the territory of the University campus, two cyberphysical factories for designing and manufacturing products in interests of the space industry and the propulsion engineering, as well as a digital factory for developing products for aviation will be put into operation.

“A cyberphysical robotic factory for development and production of small-sized gas turbine engines is being created at the University campus on behalf of our industrial partners – the UEC and “UEC-Kuznetsov.” This is the second project, the theoretical basis for which has become the conceptual model of a digital plant developed by the staff of the Advanced Aerospace Engineering School (AAES) of Samara University. Earlier we informed about creation of the cyberphysical factory for production of nanosatellites on behalf of Roscosmos. Both projects are being implemented simultaneously," said Ivan Tkachenko, Director of AAES.

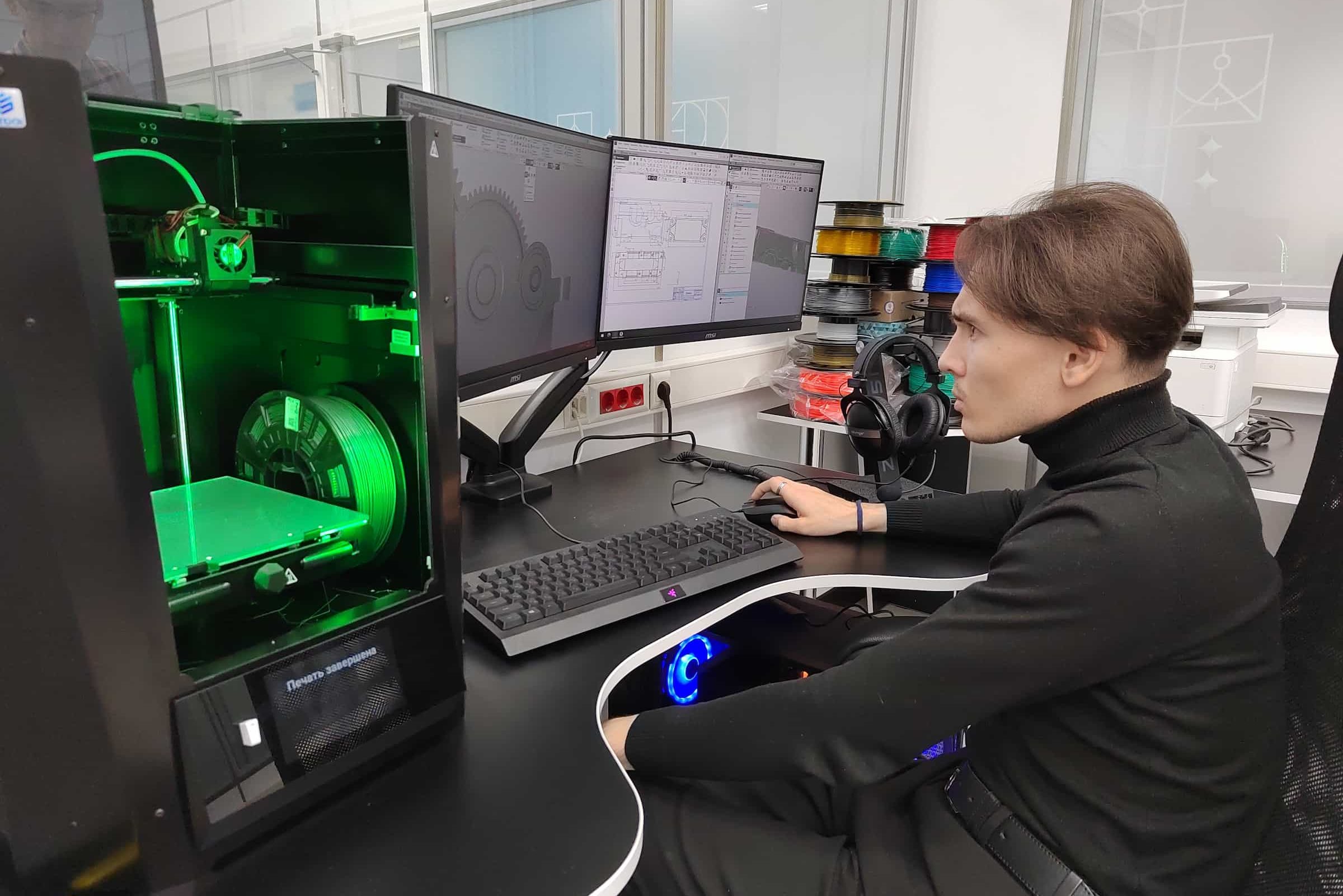

According to Victoria Kokareva, Associate Professor of the Department of Aircraft Propulsion Engineering, the cyberphysical factory (CPhF) is intended for, firstly, working out processes of digital design of gas turbine engines and technologies of their smart manufacturing on behalf of the United Engine Corporation, and secondly, training engineers who are able to create and manage digital productions. New educational spaces have already been put into operation, in which AAES employees and undergraduates work.

“We focused our attention on the smart manufacturing systems and technologies to be just implemented at our enterprises today, which these enterprises really need. We train engineering personnel skilled in such technologies and are able to launch them in real production conditions. And since our University’s principle is “Education through research,” first of all we develop and implement these technologies at our University,” explained Ivan Tkachenko.

According to Victoria Kokareva, the structure of the cyberphysical factory being created completely corresponds to the conceptual model of the digital factory, in which three hierarchical levels are provided for: digital factory — smart factory — virtual factory. Higher-level factories include lower-level ones, according to the “matryoshka principle.”

At the first level (the so-called “digital factory”), design preparation for manufacturing small-sized gas turbine engines is now being completed. Engineering and optimization calculations have already been performed using domestic digital platforms; digital twins of parts, assemblies, units have been created, forming a complex digital model of the product. The engine specifications have also been determined, with its virtual assembly and virtual tests performed.

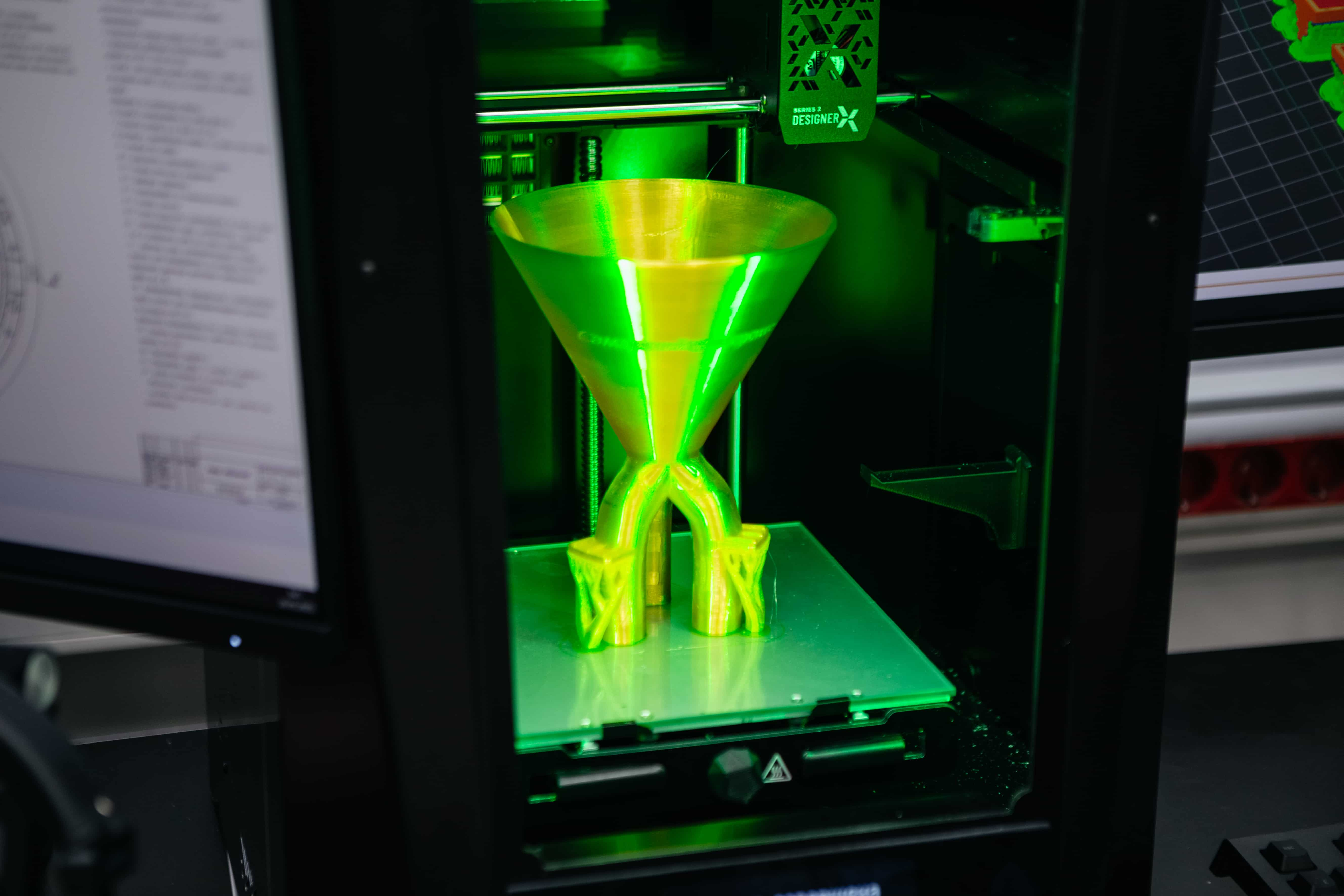

At the second — higher — level (this is a smart factory, the structure of which includes the first level), preparation of the production and manufacturing the products will be carried out. Technological preparation of the production is currently being implemented. AAES employees model technological processes of manufacturing parts given basic properties of materials and production conditions.

Developers responsible for this level focus on casting and additive technologies, machining processes involving CNC machines, simulation tools for production systems, as well as resource management and production monitoring systems. Victoria Kokareva noted that by now, using the Samara University’s equipment, a number of parts, assemblies and units of the gas turbine engine has already been manufactured.

“The key element of the smart factory that we have to create, perform its test run in conditions of the pilot production being created, and integrate in the educational process is the intelligent production cell. In future, when coming to work at the UEC enterprises, AAES graduates will be able to independently create such cells and form them into productions of any scale and with any product range,” explained Victoria Kokareva.

As for the highest — third — level of the cyberphysical factory (it is called “virtual factory”), it is an information and analytical system that includes in its structure both lower levels, managing the entire CPhF as a whole. At this level, on the basis of the Control Room, the supply chain in general will be formed, with production and economic indicators analyzed, and management decisions developed.

According to Vitaly Smelov, Director of the Institute of Engine and Power Plant Engineering (IEPPE), pilot production of small-sized gas turbine engines is to be launched in December 2023. Purchasing machine tools and robotic equipment is now being completed, and its installation will begin in the near future. The testing ground for full-scale testing and validation of digital models is being created, as well.

“One of the tasks of the Advanced Aerospace Engineering School is early career guidance of schoolchildren and the immersion of high-school pupils in project activities in the areas of the cyberphysical factory under supervision of mentors from among AAES Master’s Degree students. Meanwhile, tasks should be set by industrial partners,” said Vitaly Smelov. “Today it is important for us to involve schoolchildren in carrying out design and research work, forming the personnel reserve for “UEC-Kuznetsov” PJSC, developing creative thinking and teamwork experience in solving actual business problems of intra-factory logistics, in conditions of digital transformation. The University deploys testing grounds for developing and testing organizational and technical solutions when creating new products and technologies for manufacturing the engines. By the end of the year, the design marathon, the hackathon on simulation modeling, the technological competition and the festival of robotic systems will have been held for schoolchildren,” explained the IEPPE director.

According to Evgeny Filinov, Associate Professor of the V.P. Lukachev Department of Aircraft Engine Theory, the scope of application of the engines, the pilot production of which is going to be deployed at the University campus, is unmanned and remotely controlled aircrafts.

For reference:

The Federal Project “Advanced Engineering Schools” is implemented in framework of the State Program “Scientific and Technological Development of the Russian Federation”. Samara National Research University was competitively selected and included in 30 participants of the Federal Project “Advanced Engineering Schools” in June 2022.

Activities of the Advanced Aerospace Engineering School (AAES) of Samara University cover three interrelated areas: space engineering, aircraft engineering and information technology. The frontier engineering challenge to be addressed by the school is developing integrated solutions accelerating creation and innovation of aerospace products, as well as training the engineering personnel.

The University’s industrial partners in the Project “Advanced Engineering Schools” are SRC “Progress” (part of Roscosmos State Corporation), Rostech’s United Engine Corporation, and its Samara enterprise “UEC -Kuznetsov” PJSC, as well as “Aviakor — Aviation Plant” JSC. At present, in framework of business contacts, expanding the number of AAES’s official industrial partners is underway.

.jpg)

.jpg)

.jpg)

.jpg)