Top managers and leading specialists of the enterprise visited new educational spaces where the students of the Advanced Aerospace Engineering School and students of the enterprise’s Wings of Rostec targeted program took classes. Then, they got to know how the process of equipping the small-sized gas-turbine engine and power plant cyberphysical factory goes, checked over additive manufacturing areas and laboratories where the MGTD-22 small-sized gas-turbine engine is currently tested.

Sergey Falaleyev, Head of the Department of Aircraft Engine Construction and Design, showed the guests the Computer Engineering and Digital Technologies university laboratory. He shared the experience of introducing the CML-Bench™ digital platform of the Peter the Great St. Petersburg Polytechnic University which allows designing digital twins of various items into the educational process. It is thus platform that is currently being introduced at UEC enterprises.

In the Immersive Technologies in Propulsion Engineering laboratory representatives of UEC-Kuznetsov PJSC were told about a VR-simulator which helps to explore the aviation engine structure and repair technique using virtual reality technologies based on NK-8 model previously made at the enterprise. The complex allows visualizing the process of parts manufacturing fully using authentic virtual equipment.

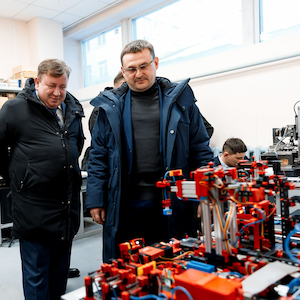

Plant representatives visited the mechanical processing workshop and the instrumentation control area at the premises of the University CAM Technology Center, and had a look at the assembled equipment of the future cyberphysical factory.

Vitaly Smelov, Director of the Institute of Engine and Power Plant Engineering, and Viktoria Kokareva, Head of the Laboratory of Intelligent Control Systems for Enterprise Management, showed the process of design-engineering preparation of manufacturing at the PLM-Lotsman digital platform. This platform is used both in UEC-Kuznetsov PJSC and in other UEC enterprises.

Production workers expressed great interest talking to the specialists of manufacturing areas with a focus on laser cladding by wire, direct laser growth (DLG), as well as selective laser melting and 3D printing of consumable patterns. It is here where the comprehensive conventional technology for additive manufacturing of parts and blocks of gas-turbine engine hot sections is developed — one which has been already handed over to be introduced at UEC-Kuznetsov PJSC.

Ivan Tkachenko, Director of the Advanced Aerospace Engineering School (AAES) introduced the delegation from the enterprise to the opportunities of the School’s new educational spaces. Here, students master the technologies of virtual reality, synthetic vision, mechatronics and robotic technologies. More specifically, they take part in development of the functionality of roboticized transport trolleys with computer vision that are supposed to transport parts and intermediates between work posts and in manufacturing site design. With the University’s laboratory bench working procedures of the cyberphysical factory are explored and modelled.

UEC-Kuznetsov PJSC is the University’s industrial partner in the framework of the Advanced Engineering Schools Federal Project, and the technologies that are supposed to be worked out at the small-sized gas-turbine engine cyberphysical factory will be subsequently transferred to the enterprise, as well as the ITAE alumni that once participated in their development.

Aside from looking at laboratories and educational spaces, representatives of UEC-Kuznetsov PJSC listened to the reports on research, development and engineering works executed by the Samara University in the interests of the enterprise.

Alexander Yermakov, Research Advisor of the propulsion engineering design bureau (DB-203) announced that digital design of a universal gas generator had been completed. He rationalized key technical decisions made by a group of developers based on global trends and technologies applied at the UEC-Kuznetsov enterprise and stated that such a gas generator could serve as a basis for manufacturing of civil aviation gas-turbine aviation engines of the 5+ generation. That said, DB-203 Research Advisor emphasized that it would be impossible to apply the methods used to make the engines of the 4th generation to design the engines of the 5+ and the 6th generations.

“We have completed in-depth research of the gas generator as a technical project. It’s a versatile construction that can be used as a basis to make promising engines with the propulsion power of 180 kN and 260 kN. We have ensured working efficiency of all the blocks as well as required parameters that meet the terms of reference,” Alexander Yermakov said.

According to Pavel Chupin, Chief Design Officer of UEC-Kuznetsov PJSC, in 2024, the enterprise intends to start issuing work drawings for some key parts of the gas generator together with the Samara University.

Vladimir Pavlov, Deputy Chief Design Officer of UEC-Kuznetsov PJSC for Research and Development, suggested delegating manufacturing of those parts to the additive technology manufacturing sites of University.

Also, Vladimir Pavlov defined the tasks for AAES in 2024 in the framework of its cooperation with UEC-Kuznetsov PJSC as an industrial partner. According to him, in 2023, AAES implemented 10 projects in the interests of the enterprise. Nine of them will be continued, and two more will be launched in the upcoming year. The terms of reference for them have already been agreed upon and approved by the enterprise.

Evgeny Filinov, Senior Researcher of RDL-207, briefed representatives of the enterprise with the results obtained in the process of designing a small-sized gas turbine power plant with a capacity of 80 KW, including the issues regarding the item’s patent purity and patent protection explored together with the Federal Institute of Industrial Property. Among the results of this joint work is a patent for the original structure of a heat-exchange unit designed in accordance with the technological capabilities of UEC-Kuznetsov PJSC. In total, 9 applications were submitted to Rospatent.

In the course of discussion, Alexei Sobolev, Managing Director of UEC-Kuznetsov PJSC, advised the developers to find the technical solutions that would allow expanding the market niche where the supply plant is sought after as much as possible to go beyond the needs of gas and oil companies.

“Big and ambitious tasks need to be set. Aside from a direct need of gas producing and oil companies for small-sized gas-turbine power plants, these plants should be sought-after everywhere where small-scale power generation exists. It can be achieved if the plant turns out as simple as possible in terms of its structure and undemanding in terms of maintenance,” Alexei Sobolev noted and suggested holding another working meeting on this project in January 2024.

Vladimir Bogatyrev, Rector of Samara University, supported the suggestion and in his turn suggested discussing the options for cooperation between the University and the enterprise in the process of subsequent manufacturing of a small-sized power plant.

“Practical experience offers universities several forms of interaction with their partners in the process of joint production. I am sure that our joint decision will meet the interests of both sides and enable cooperation between the Samara University and UEC-Kuznetsov PJSC,” Rector emphasized.