Student of Samara University has developed a lightweight and economical electric heater in the form of a flexible and very thin film, like two sheets of paper, which can be glued to an object in need of protection from the cold.

Such a heating film, inside which there is an innovative heating element, will be able to effectively warm not only smartphones and other portable electronics in the winter cold, but also electric car batteries, which will ultimately help expand the geography of the use of electric cars in Russia and increase sales of such cars. This project was successfully defended as a final qualifying work in the form of a student startup.

"As you know, batteries used in various electronic devices are extremely sensitive to low temperatures and discharge very quickly in the cold. We have developed a special ultrathin flat heater that will maintain an optimal temperature in battery systems and gadgets, while it will be very economical, consuming a minimum of energy," said Bulat Khalitov, the heater's developer, a fourth-year student at Institute of Aerospace Engineering of Samara University.

The heater will receive electricity from the very battery that it is supposed to warm — it is planned in the future to come up with its own system for connecting and disconnecting the heater for different devices. At the same time, the operation of an economy "electric heating pad" will affect the battery discharge rate to a much lesser extent than cold weather.

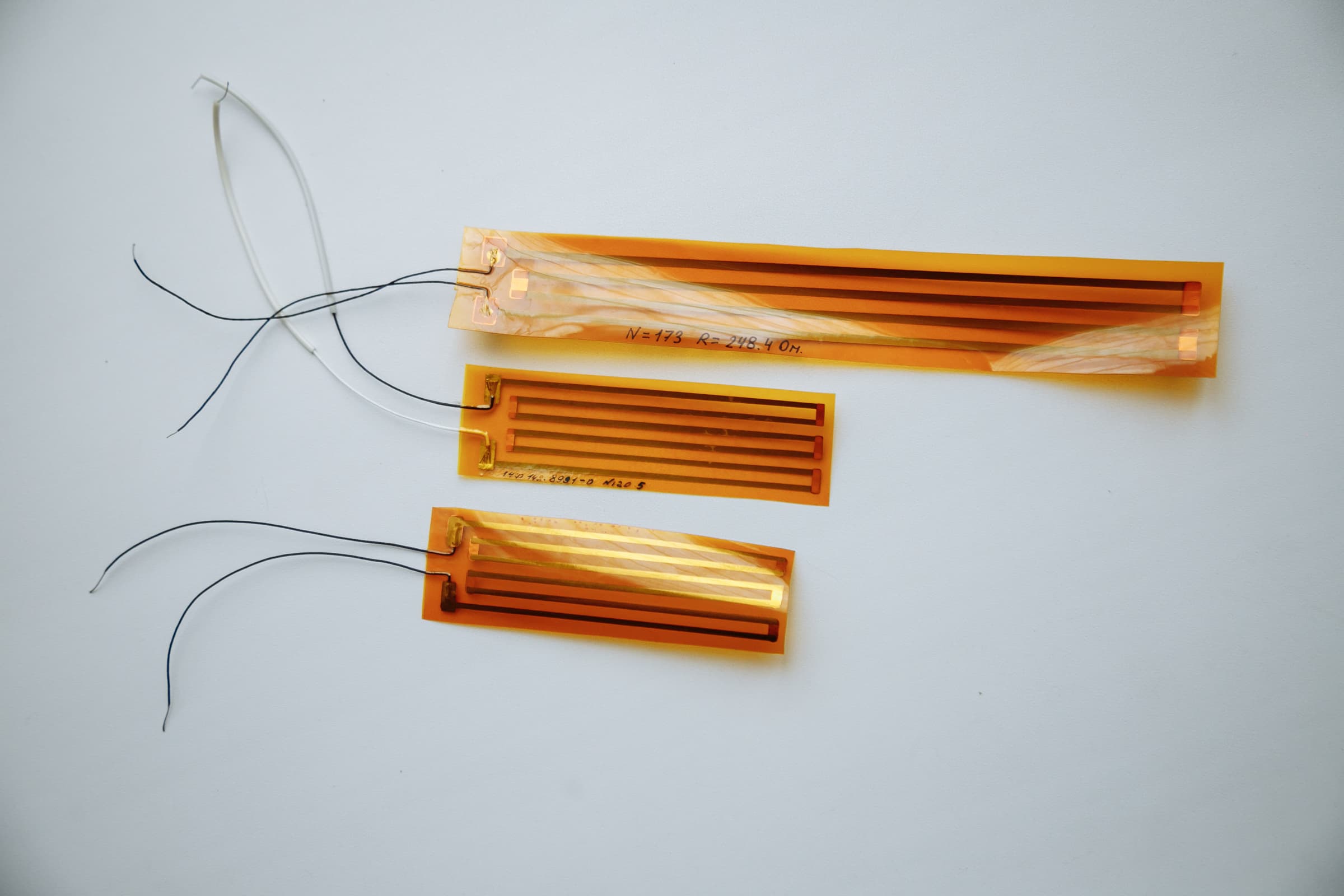

Structurally, the heating film, the total thickness of which is only about 0.2 mm, consists of a heat-resistant polymer base with a thickness of up to 50 microns (0.05 mm) and two thin functional layers created using the vacuum ion-plasma method. First, the first functional layer with a thickness of up to 25 microns is applied to the polymer base by depositing an ion-plasma stream in a vacuum. Inside it, during crystallization, special "nanopillars" are formed, oriented in approximately the same direction — almost like the needles of a frightened hedgehog. This layer is then heated due to the flow of electric current through it during the operation of the heater, and the "nanopillars" provide the necessary properties of the heating layer.

"Due to the selection of a special material and control of the vacuum ion-plasma deposition process, columnar nanostructured crystallites of the first coating layer with a very high electrical resistivity are obtained during the deposition process," explained Bulat Khalitov.

Then, a second layer (also up to 25 microns thick) is applied to the heating layer by the same vacuum ion-plasma method, it has a higher coefficient of thermal conductivity, and its task is to effectively remove the generated heat in the direction of the object being protected from cold. After that, special connectors are installed to supply power and this entire heating "sandwich" is sealed from all sides using a temperature-resistant polymer base. The main thing then during operation is to fix or glue the heater on the heated object with the correct side.

According to Bulat Khalitov, among the competitive advantages of such a heater compared with similar devices on the market is a very small thickness, flexible design and low energy consumption due to high electrical resistivity — about 3 ohms mcm. The maximum permissible heating temperature of the structure is 150 °C. The supply voltage can vary widely — from 1 to 220 V. The service life of such a heater should be about 50 thousand hours.

"The vacuum ion-plasma method for obtaining the first functional layer with a high electrical resistivity — 3 times greater than that of nichrome — and a small thickness of the resistive layer allows you to create small-sized flat electric heaters with a heat flux density of 1 kW/m2, which is sometimes simply impossible or very laborious to create using other technologies. This is perhaps the most compact of the existing types of electric heaters with high performance," said Mikhail Giorbelidze, Chief Scientific Consultant of the project, senior lecturer at the Department of Aircraft Production and Quality Management in Mechanical Engineering, head of the NICh-90 Special Coatings Department at Samara University.

So far a prototype heater has been created, the first tests have been carried out. The development is planned to be patented. A small enterprise project for the production of such products is ready, and investors are being sought. Developers see the potential use of devices created using such technology not only in the field of portable gadgets — smartphones and power banks, but also in the automotive industry — for heating electric car batteries.

"The first market for our heaters may be the domestic market of electric vehicles. It is planned to produce several product samples on the basis of the university for visual demonstration in dealerships of the effectiveness and expediency of this product. This heater can be optionally installed directly on the batteries of electric cars. With our development, electric vehicles can be used in winter at lower temperatures, which in the future will expand the geography of sales of electric cars, for example, at the expense of the northern regions of Russia," said Bulat Khalitov.

For reference:

Samara University is successfully implementing the Startup as a Diploma program aimed at involving talented students in the development of the ecosystem of technological entrepreneurship, as well as supporting businesses at an early stage. The program allows a student or a team of students to develop a real business project and, based on it, defend a diploma in the format of a final qualifying work. A student of any field of study, specialty and level of education can become a participant in this program. This year, 26 startup projects developed by more than 60 students were presented to the expert commission at the University's Startup Center.