Preparing for mass production and transferring to industrial partners the line of small-size aircraft and rocket engines and components for them is the goal to be set at the Advanced Aerospace Engineering School (AAES) of Samara National Research University.

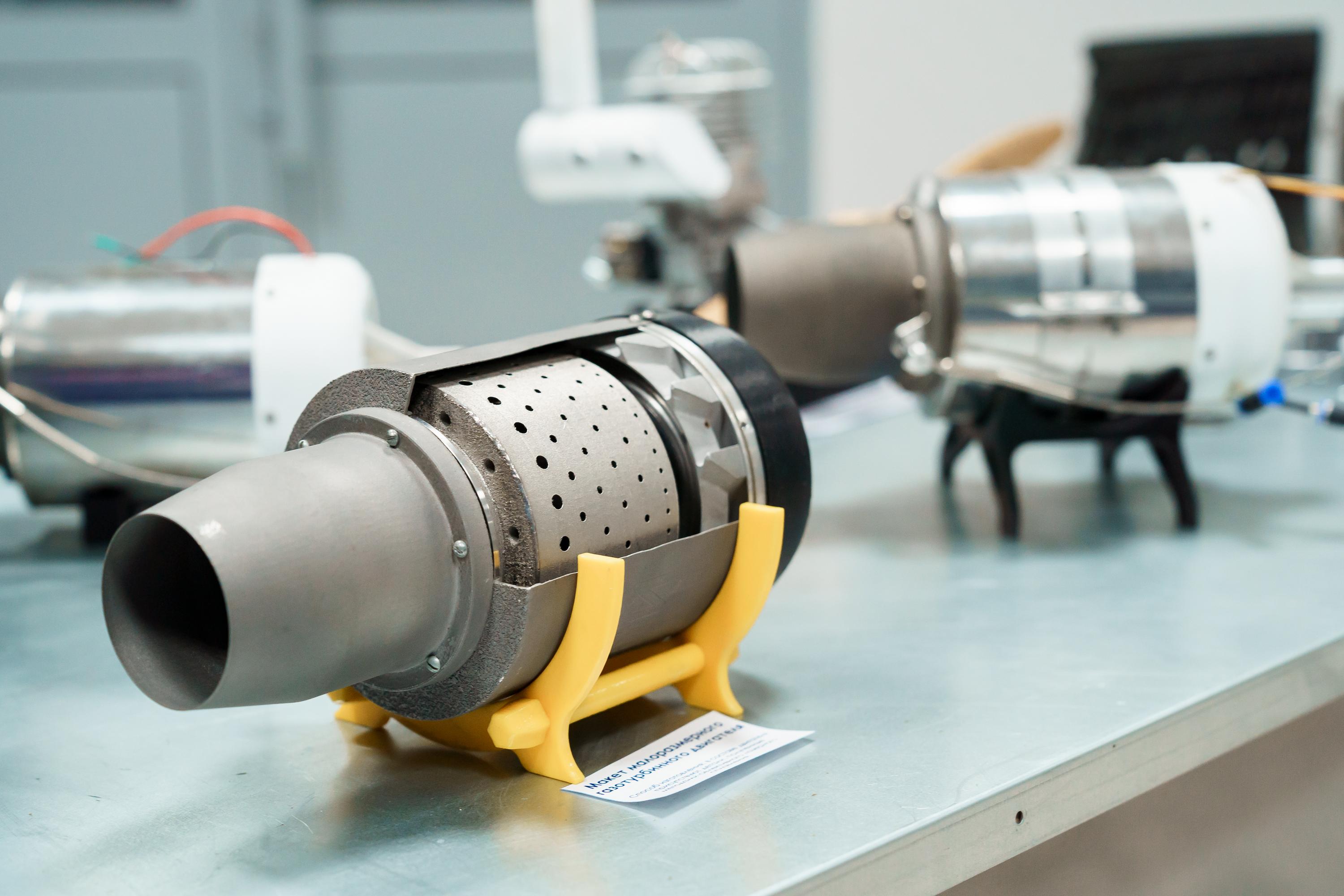

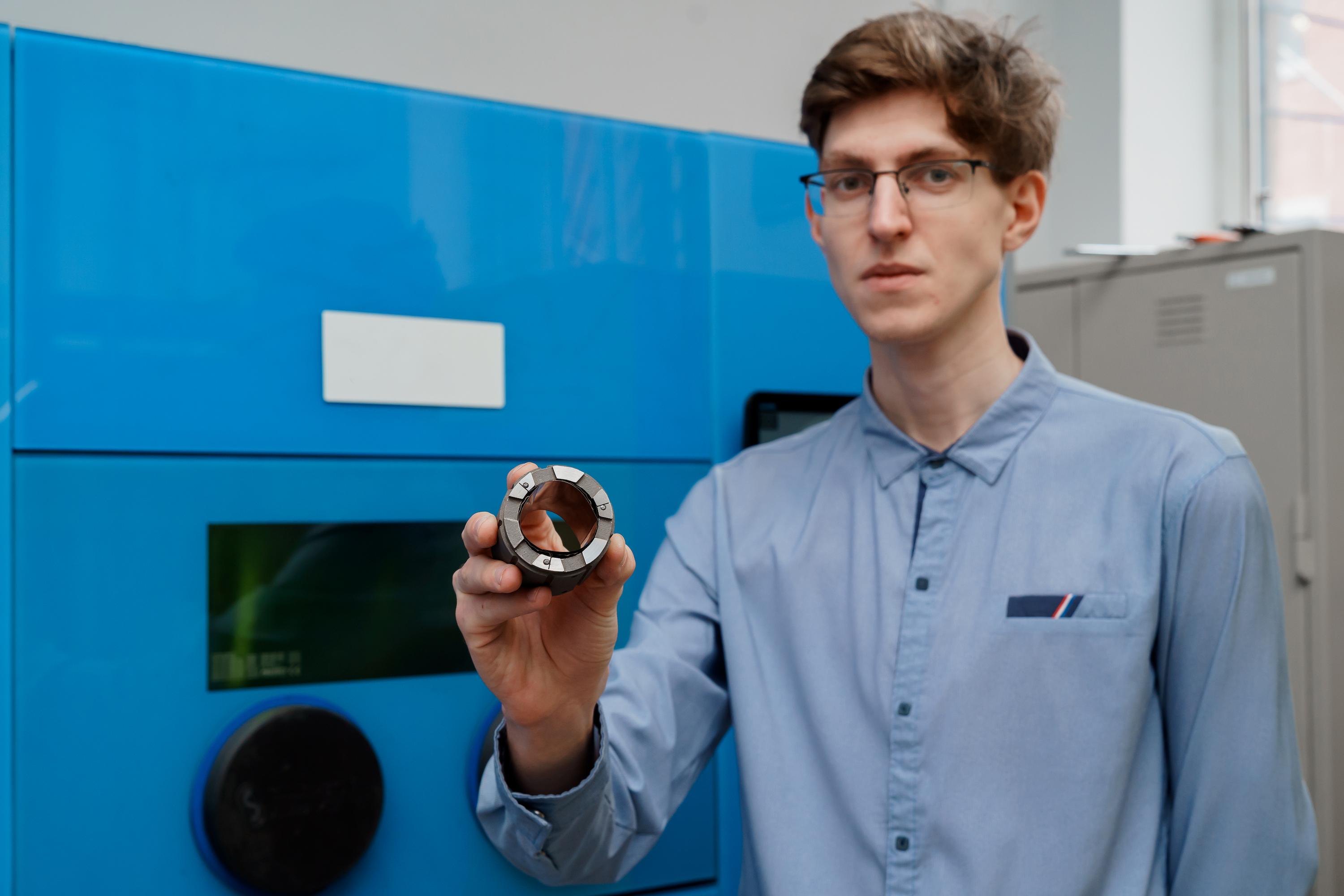

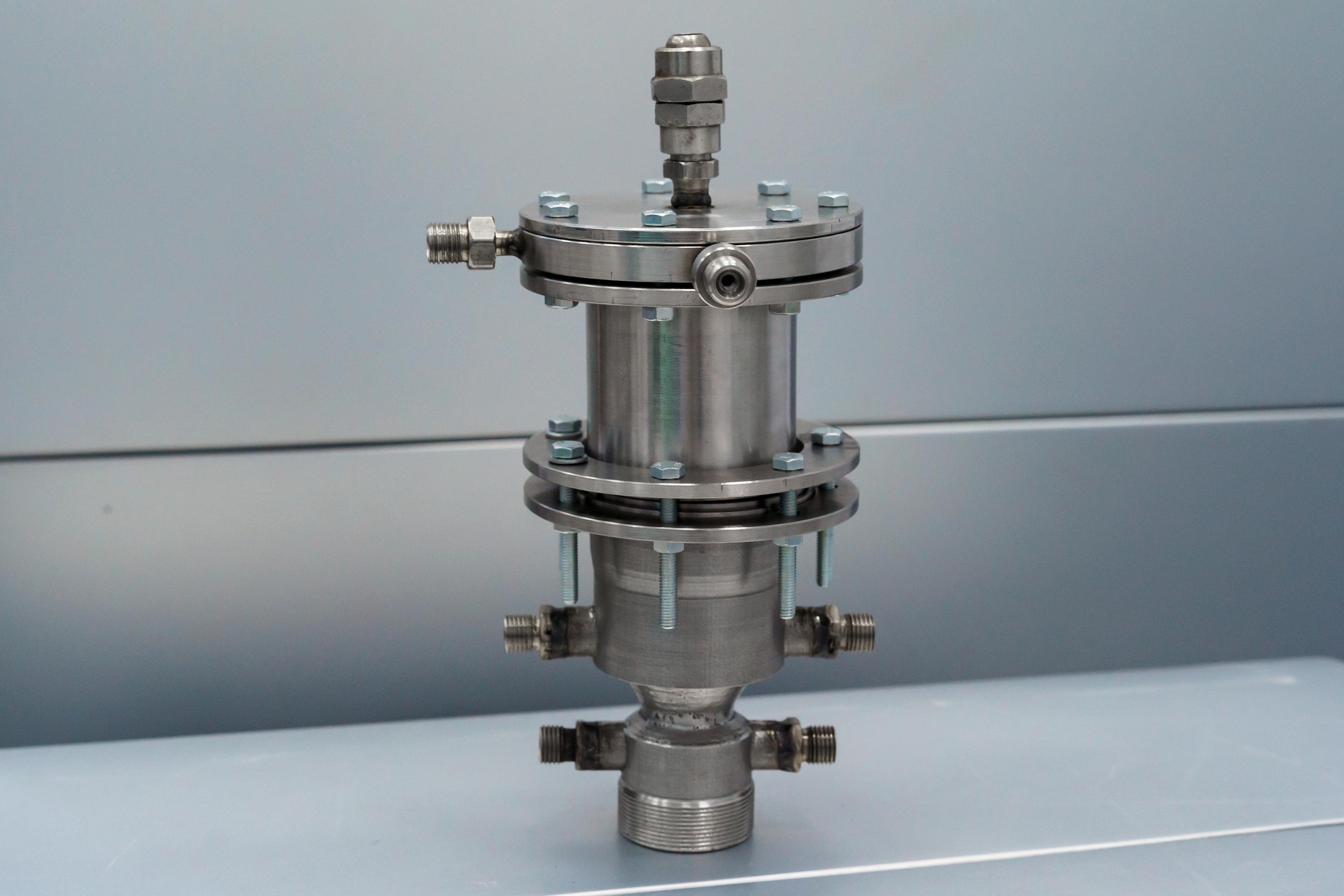

The complex project to be implemented at the AAES, has combined four developments by the Institute of Engine and Power Plant Engineering, which have reached the stage of applied R&D. These are the small MGTD-20 "Kolibri" gas turbine engine with its thrust of 20 kgf, the single-cylinder piston aircraft engine APD-5 with its capacity of 5 hp, the liquid-propellant low-thrust rocket engine ZHRD MT, and the lobed gasodynamic bearing for a promising gas turbine engine with its thrust of 150 kgf.

As explained by Ivan Tkachenko, Deputy Rector and Director of the Advanced Aerospace Engineering School, the integrated project included such products, demonstrators and prototypes, which can be manufactured and tested directly at the University.

"We have focused on creating small-size engines for aerospace engineering, since Samara University has not only all the competencies for their design, but also the production base for manufacturing the evaluation units, as well as for testing and fine-tuning the prototypes. In the country, there is an urgent need for domestic small-size aircraft engines and power plants, and our developments will make it possible for the industrial partners to enter their mass production. This will undoubtedly strengthen Russia’s technological independence", emphasized Ivan Tkachenko.

In the process of creating the engines and their components under the auspices of the AAES, digital technologies for designing and virtual testing of such products are developed and improved, as well as technological processes for their automated production are designed, given capabilities of industrial partners and serial production.

"Within the project, progressive design, technological and production solutions are being tested at one of the cyber-physical factories of the Advanced Aerospace Engineering School. This fully corresponds to the frontier task facing the AAES, which is focused on the development of integrated technologies within the digital-factory concept", said Vitaly Smelov, Deputy Director of the AAES and Scientific Supervisor of the project.

During the work on the complex project, the TRL (technical readiness level) of the products has risen from 3-4 to 6. The APD-5 piston engine, the small-sized rocket engine ZHRD MT, and the lobed gasodynamic bearing are presented by their operating demonstrators to be tested in the laboratory conditions. And the MGTD-20 “Kolibri” is presented in the form of 10 prototypes.

"Bench tests of the small-sized gas turbine engine "Kolibri" are underway on a wide front with high intensity. To date, 5 out of 10 manufactured prototypes have been involved in testing, and the first one has already fully exhausted its resource. Given the results obtained, we make changes to the engine design, test new technical solutions, and improve operational specifications. In coordination with the industrial partner, we focus on the fact that "Kolibri" will be mass-produced in an amount of at least 10 thousand. Units", told Ivan Zubrilin, Associate Professor at the AAES and Responsible Executor for the project.

According to him, as part of the complex project, the conceptual design environment for ASTRA-GTD gas-turbine power plants has been modernized, sets of preliminary design documentation have been released, as well as sets of preliminary technological documentation for manufacturing the demonstrators and prototypes of the engines and bearings.

During the tests, fuel compositions for the small-sized gas turbine engine were explored and the optimal chemical composition of the fuel was identified. For the gas-turbine, piston and liquid rocket engines, VR models of the operating process have been developed. All the results obtained are uploaded to the unified information environment based on the digital platforms CML-Bench and Lotsman:PLM.

In future, the AAES specialists will design intelligent production cells (IPCs) for the robotic production of MGTD-20 "Kolibri". This is being carried out on the basis of the cyber-physical factory of small-sized gas-turbine engines, which is part of the AAES structure. A simulation model of production processes has now been developed, which will allow making optimal solutions when creating the cells.

As noted by Vitaly Smelov, the complex project on creating small-size engines for aerospace technology is deeply integrated into the educational activities of the AAES 15 students of the Advanced Aerospace Engineering School proactively participated in the research and development work. Two educational programs for advanced training of engineering personnel have been developed and launched.

For reference:

The Advanced Aerospace Engineering School "Integrated Technologies in Development of Aerospace Engineering" (AAES) at Samara National Research University was established in 2022 on a competitive basis within the framework of the Federal Project "Advanced Engineering Schools" (AES). The "first wave" of the project was participated by 89 Russian universities, and 30 best of them were selected for the AES to be organized.

The AAES is aimed at forming the new model of engineering education based on the principles of the digital factory organization, providing scientific, technical and personnel support for Russia’s advanced development in solving the problems of designing new-generation aerospace products.

Till 2030, the expected outcomes of the activities by Samara University’s Advanced Engineering Aerospace School shall be as follows:

· 15 new educational programs;

· over 1.5 thousand graduates of the AAES employed in the aerospace industry;

· 15 new modern educational spaces;

· 3 pilot production facilities.

Currently, there are 311 students at the AAES. 11 educational programs of higher education have been launched: 4 programs at the bachelor’s degree level and 7 programs – at the master’s degree level, as well as 3 programs – within the advanced professional education. 17 new educational spaces have been opened. The first graduation from the AAES, including 58 people, took place in 2024.

There are 6 basic themes for the scientific work at the AAES. The AAES has 6 laboratories, 8 interactive complexes for advanced training of engineering personnel, and 3 pilot production facilities:

· cyber-physical factory of small-sized gas-turbine engines,

· cyber-physical factory of small spacecrafts;

· digital factory of regional aviation and unmanned aerial vehicles.

RU

RU  EN

EN  CN

CN  ES

ES